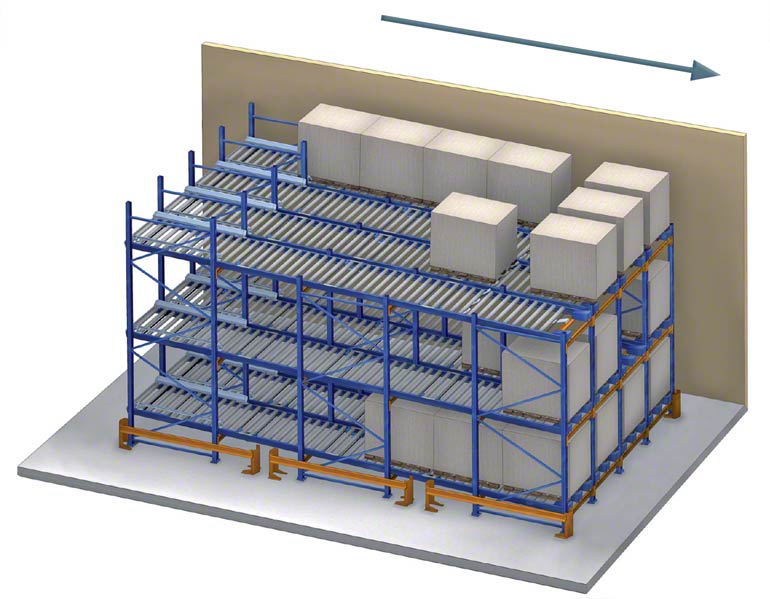

Flow Thru Pallet Racking

Cargo was put from back of racking and unload from front of racking.

Flow thru pallet racking. The full benefit of pallet flow is maximized when the vertical space in your warehouse is used for multi level installations. The system can be made out of roll formed more economical or structural less susceptible to damage steel. It s a good solution for food industry. With pallet flow you can achieve high density storage while maintaining a fifo retrieval order.

Pallet flow systems can be designed to hold up to 20 pallets deep in one lane and allow for quick and efficient inventory turnover. Pallet flow rack storage systems are used for high density first in first out pallet storage. Drive in and drive thru racks are optimal for large inventories of relatively few sku s. Pallet flow racking maximizes actual storage space by minimizing aisles.

Pallets are inserted at the highest degree of incline on the pallet flow and are pulled by gravity to the other end of the rack where they are to be picked. Row spacer wall ties. Blog 320 485 4974chatget a quote identifying racking systems what is pallet flow racking. It s widely used in warehouse and assembly workshop distribute center.

Then pallets glide safely and effortlessly at a controlled rate to the front of the storage lane. Row spacers are used to space back to back pallet rack bays while providing rigidity in your pallet rack system. Wall ties are used in some cases where you have single bays of pallet racking along a wall for example. Allow 3 of overhang of your pallet in the front and rear of the pallet rack bay.

Pallet flow rack is for full pallet picking and will require minimal aisles because pallet loads are stored back to back flush in the rack. Usually flow through racking is suitable for plastic box or carton the space can be used by 50. Flow through racking can be used for standard size carton it have automatically replenishment function when first carton was pick out the next one will reach first one s position automatically. In this first in first out fifo system pallets are loaded at the top end of the slightly inclined rack.

In a pallet flow system pallets sit on a track of durable skate wheels with the racking positioned at a downward sloping angle to make the system gravity driven. Pallet flow racks fully utilize available storage space and ensure the picking aisle has access to stocked pallets. Pallet flow rack is designed to be a high density first. Pallet flow rack also known as gravity flow is a fifo first in first out dynamic storage system.

Pallet flow racking is a first in first out racking system fifo that utilizes gravity flow roller tracks to form a gravity flow lane. Deep land pallet flow rack allows more pallets to be stored and uses electro mechanical or pneumatic speed braking systems to slow the loads down and keep them contained in the pallet racking.