Granite Surface Plate Calibration Procedure

We can certify your surface plate to grade aa laboratory grade grade a inspection grade or grade b toolroom grade.

Granite surface plate calibration procedure. This method is more complex and the necessary equipment is more expensive than the equipment used in the alternative method. Pour a small amount of surface plate cleaner on a clean soft cloth and wipe the surface of the granite. Surface plates wear over time and must be properly maintained to ensure flatness and continued precision measurement. Surface plate calibration maintaining granite surface plates.

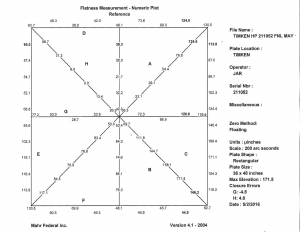

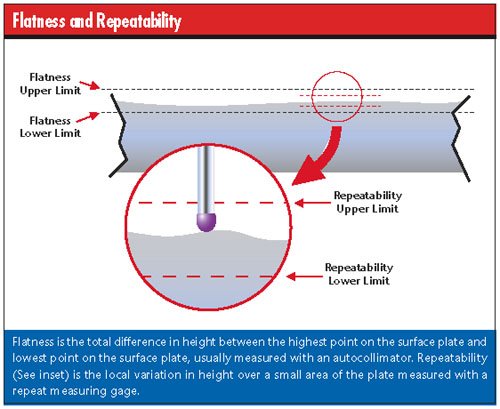

Surface plate calibration is the only sure way to know that you are working with a level surface and can expect accurate workmanship when the surface plate is in use. Excluding those contained in other quality standards such as iso iec 17025 the minimum fed. Your granite surface plate granite block granite table is the foundation of all accurate measurements optimal calibration has the ability to achieve extremely tight tolerances to ensure that your are getting the most precise measurements possible. There are two methods for inspecting surface plates the best method inspects overall flatness of the plate surface using an autocollimator.

Clean the granite surface plate prior to calibration. Immediately dry the cleaner off the surface plate with a dry cloth. Do not allow the cleaning liquid to air dry. Our reports contain a significant amount of both critical and pertinent information.

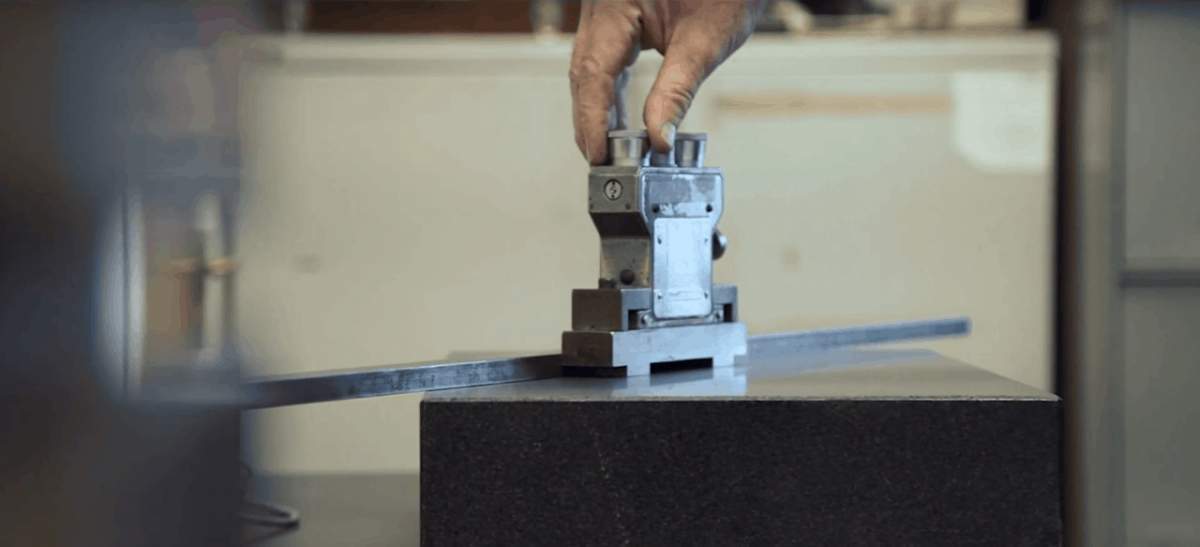

In this video we see the process for inspection and reconditioning granite surface plates. Surface plate this calibration procedure covers the inspection of surface plates. The plates are inspected and calibrated with an autocollimator and. Requires most of the information we provided.

Because every linear measurement depends on an accurate reference surface from which final dimensions are taken surface plates provide the best reference plane for work inspection and layout prior to machining. Place a repeat measuring gauge on the center of the granite surface plate. The top work surface is lapped flat and smooth to provide a critical reference surface for many types of dimensional measurements. Surface plates are made of various types of granite they are massive stiff and hard.

The quality of surface plates had been standardized for decades through the federal specification ggg p 463c. Granite is the most widely used material for the. For each surface plate repair and calibration we provide detailed professional reports. They are used by tool rooms machine shops and inspection and calibration laboratories because of certain advantages that they have over steel surface plates.